Introduction

In today's modern world, access to electricity is a necessity for various operations, whether it be for residential, commercial, or industrial purposes. However, there are many remote locations where access to the power grid is limited or non-existent. In such cases, diesel generators play a crucial role in providing a reliable power supply. This article will delve into the intricacies of diesel generators for remote power supply, discussing their benefits, working principles, maintenance requirements, and environmental impact.

Benefits of Diesel Generators for Remote Power Supply

Diesel generators are widely used in remote locations for several reasons. One of the primary advantages of diesel generators is their reliability. Diesel engines are known for their robustness and durability, making them ideal for continuous operation in harsh environments. This reliability is crucial in remote locations where access to maintenance and repair services may be limited.

Another key benefit of diesel generators is their fuel efficiency. Diesel engines are more fuel-efficient than their gasoline counterparts, providing more power output per unit of fuel consumed. This fuel efficiency is essential in remote locations where fuel availability may be limited, making diesel generators a cost-effective solution for long-term power supply.

Furthermore, diesel generators are known for their high power output capabilities. They can provide a significant amount of power, making them suitable for a wide range of applications, from powering small homes to large industrial facilities. This versatility makes diesel generators a popular choice for remote power supply needs.

Working Principles of Diesel Generators

Diesel generators operate on the principle of converting diesel fuel into mechanical energy, which is then converted into electrical energy. The basic components of a diesel generator include the diesel engine, alternator, fuel system, cooling system, and control panel.

The diesel engine is the heart of the generator and is responsible for converting the chemical energy stored in diesel fuel into mechanical energy through the process of combustion. The alternator, also known as the generator, converts the mechanical energy produced by the engine into electrical energy through the process of electromagnetic induction.

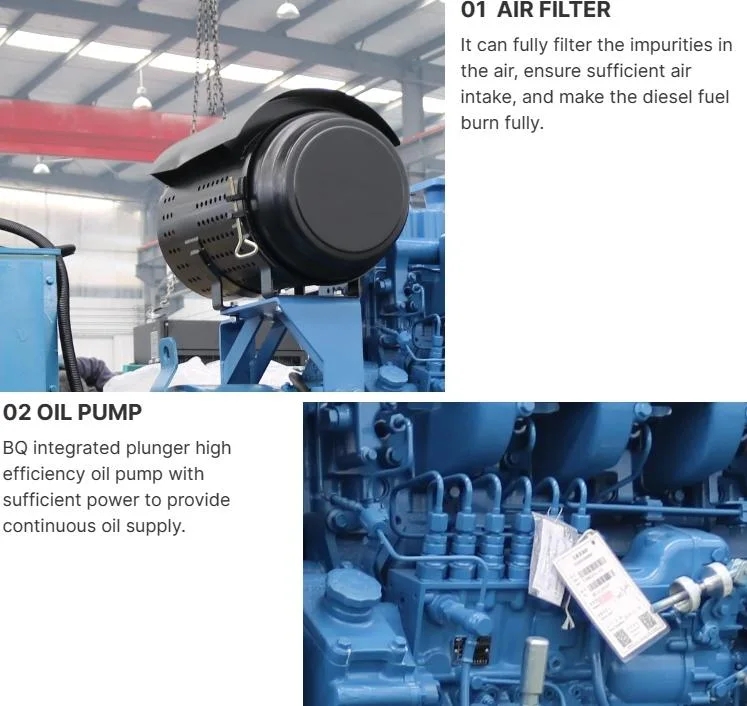

The fuel system of a diesel generator consists of a fuel tank, fuel pump, fuel injectors, and fuel filters. The fuel pump delivers diesel fuel from the fuel tank to the fuel injectors, where it is sprayed into the combustion chamber for ignition. bojinsi ensure that the fuel entering the engine is clean and free from contaminants.

The cooling system of a diesel generator is essential for maintaining the optimal operating temperature of the engine. It typically consists of a radiator, cooling fan, and coolant pump, which work together to dissipate the heat generated during the combustion process.

The control panel of a diesel generator houses the various electrical components responsible for regulating the operation of the generator. It allows users to start and stop the generator, monitor power output, and configure settings such as voltage and frequency.

Maintenance Requirements of Diesel Generators

Proper maintenance is essential for ensuring the reliable operation of diesel generators in remote locations. Regular maintenance tasks include:

1. Fuel Quality: The quality of diesel fuel used in the generator plays a crucial role in its performance and longevity. It is essential to use high-quality diesel fuel that is free from contaminants and water to prevent damage to the engine.

2. Oil Changes: Regular oil changes are necessary to keep the engine properly lubricated and prevent excessive wear and tear. It is recommended to follow the manufacturer's guidelines for oil change intervals and use the appropriate grade of oil for the engine.

3. Air Filter Cleaning: The air filter of the generator should be regularly cleaned or replaced to ensure proper airflow to the engine. A clogged air filter can restrict airflow and lead to reduced engine performance.

4. Cooling System Maintenance: The cooling system of the generator should be inspected regularly for leaks or blockages. The coolant level should be checked and topped up as needed to prevent overheating of the engine.

5. Battery Inspection: The battery of the generator should be inspected for signs of corrosion, leaks, or damage. It is essential to keep the battery terminals clean and tight to ensure proper starting of the generator.

6. Regular Testing: Periodic load testing of the generator is crucial to ensure that it can handle the required power output. Testing the generator under load conditions simulates real-world scenarios and helps identify any potential issues before they escalate.

Environmental Impact of Diesel Generators

While diesel generators offer numerous benefits for remote power supply, they also have environmental implications that need to be considered. One of the primary concerns associated with diesel generators is their emissions of pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO).

NOx emissions from diesel generators contribute to air pollution and can have adverse effects on human health and the environment. PM emissions, consisting of tiny particles suspended in the air, can cause respiratory problems and contribute to smog formation. CO emissions are a colorless, odorless gas that can be harmful when inhaled in high concentrations.

To mitigate the environmental impact of diesel generators, several measures can be implemented:

1. Use of Cleaner Fuels: Switching to cleaner-burning diesel fuels with lower sulfur content can help reduce emissions of pollutants such as NOx and PM. Ultra-low sulfur diesel (ULSD) is a cleaner alternative that produces fewer harmful emissions.

2. Emission Control Technologies: Installing emission control devices such as diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems can help reduce emissions of NOx and PM from diesel generators. These technologies work by filtering out or converting harmful pollutants into less harmful substances.

3. Proper Maintenance: Regular maintenance of diesel generators is essential for ensuring optimal performance and reducing emissions. Properly maintained engines are more fuel-efficient and produce fewer emissions compared to poorly maintained engines.

4. Alternative Power Sources: In some cases, alternative power sources such as solar panels, wind turbines, or hydroelectric generators can be used as a cleaner and more sustainable alternative to diesel generators. These renewable energy sources produce electricity without emitting harmful pollutants.

Conclusion

Diesel generators play a vital role in providing reliable power supply to remote locations where access to the power grid is limited. Their benefits, including reliability, fuel efficiency, and high power output capabilities, make them a popular choice for various applications. Understanding the working principles, maintenance requirements, and environmental impact of diesel generators is essential for ensuring their optimal performance and minimizing their environmental footprint. By implementing proper maintenance practices and adopting cleaner technologies, diesel generators can continue to be a reliable and sustainable solution for remote power supply needs.